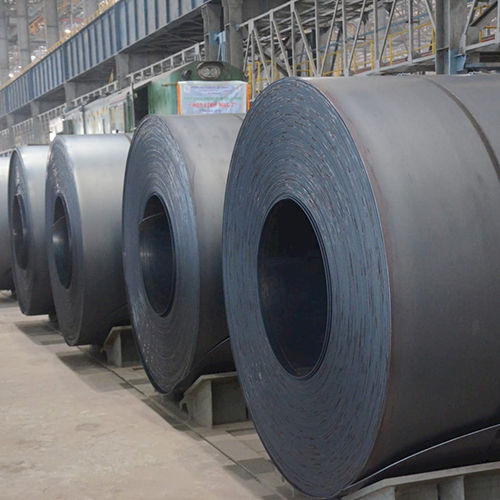

Sail Hr Coil

Product Details:

- Surface Treatment Mill Finish

- Material Steel

- Technique Hot Rolled

- Grade IS 2062 / ASTM A36 / S235JR

- Coil Thickness 1.6 mm to 16 mm

- Coil Weight 8-25 MT

- Coil Length Customized as per requirement

- Click to View more

-

Share Your Product:

Sail Hr Coil Price And Quantity

- 48 INR/Kilograms

- 2 Ton

Sail Hr Coil Product Specifications

- Customized as per requirement

- As per standard (customizable)

- Construction, automotive, engineering, fabrication

- IS 2062 / ASTM A36 / S235JR

- 8-25 MT

- Hot Rolled

- Mill Finish

- Steel

- 1.6 mm to 16 mm

Sail Hr Coil Trade Information

- 100 Ton Per Month

- 2 Days

Product Description

Conversation with Gemini

Cr Fastner Coil discreption

-

Query successful

The term "CR Fastener Coil" most likely refers to Cold Rolled (CR) steel coil that is specifically used in the manufacturing of fasteners or related components.

Here is a general description, focusing on the "Cold Rolled Coil" aspect, as this is the raw material:

Cr Fastner Coil discreption

-

Query successful

The term "CR Fastener Coil" most likely refers to Cold Rolled (CR) steel coil that is specifically used in the manufacturing of fasteners or related components.

Here is a general description, focusing on the "Cold Rolled Coil" aspect, as this is the raw material:

1. What a CR Coil Is (Cold Rolled Coil)

-

Manufacturing Process: CR (Cold Rolled) coils are produced from hot-rolled steel that is further processed at or near room temperature. This involves passing the steel through a series of high-precision rollers (cold rolling process).

-

Resulting Properties (compared to hot-rolled steel):

-

Superior Surface Finish: They have a smooth, clean surface, ideal for applications requiring a high-quality finish, like painting or plating (common for many fasteners).

-

Tighter Dimensional Accuracy: Cold rolling provides excellent control over thickness and flatness, resulting in very precise dimensions.

-

Increased Strength: The process increases the steels tensile and yield strength, making the material stronger and harder.

-

Improved Formability/Ductility (if annealed): Depending on the final processing (such as annealing, which results in CRCA - Cold Rolled Closed Annealed), the material can also have excellent ductility and formability, which is essential for stamping, bending, or drawing into complex shapes like certain fasteners.

-

Manufacturing Process: CR (Cold Rolled) coils are produced from hot-rolled steel that is further processed at or near room temperature. This involves passing the steel through a series of high-precision rollers (cold rolling process).

-

Resulting Properties (compared to hot-rolled steel):

-

Superior Surface Finish: They have a smooth, clean surface, ideal for applications requiring a high-quality finish, like painting or plating (common for many fasteners).

-

Tighter Dimensional Accuracy: Cold rolling provides excellent control over thickness and flatness, resulting in very precise dimensions.

-

Increased Strength: The process increases the steels tensile and yield strength, making the material stronger and harder.

-

Improved Formability/Ductility (if annealed): Depending on the final processing (such as annealing, which results in CRCA - Cold Rolled Closed Annealed), the material can also have excellent ductility and formability, which is essential for stamping, bending, or drawing into complex shapes like certain fasteners.

-

2. "Fastener Coil" Application

When specified as a "Fastener Coil," the Cold Rolled steel coil is intended for use as the raw material for:

-

Stamping and forming components of fasteners (such as washers, clips, brackets, etc.).

-

Producing threaded inserts (often helical coil inserts) used to repair or reinforce threads in softer materials. These inserts are often cold-formed from high-strength stainless steel wire, which is a form of cold-rolled material.

-

Manufacturing other small metal parts or components within a fastening or joining system that require precision and a high-quality surface finish.

When specified as a "Fastener Coil," the Cold Rolled steel coil is intended for use as the raw material for:

-

Stamping and forming components of fasteners (such as washers, clips, brackets, etc.).

-

Producing threaded inserts (often helical coil inserts) used to repair or reinforce threads in softer materials. These inserts are often cold-formed from high-strength stainless steel wire, which is a form of cold-rolled material.

-

Manufacturing other small metal parts or components within a fastening or joining system that require precision and a high-quality surface finish.

3. Typical Specifications (Can vary widely)

Specifications depend heavily on the final fastener product, but generally include:

-

Material: Often Mild Steel (Low Carbon Steel) or Stainless Steel, depending on the required corrosion resistance and strength.

-

Thickness: Typically ranges from very thin (e.g., 0.2 mm) up to a few millimeters (e.g., 3.0 mm), depending on the specific part being manufactured.

-

Grade: Specified according to international standards (e.g., IS 513 in India, or various JIS, EN, ASTM standards) to ensure the correct chemical composition and mechanical properties (like tensile strength and yield strength).

-

Surface Treatment: The final product made from the coil may receive various coatings (like galvanization, zinc plating, etc.) for added corrosion resistance.

Cr Narrow Coil discreption

-

Query successful

A CR Narrow Coil is essentially a Cold Rolled (CR) steel coil that has been processed to a smaller or "narrow" width, typically through a secondary manufacturing step called slitting.

Here is a breakdown of its description, properties, and common uses:

Specifications depend heavily on the final fastener product, but generally include:

-

Material: Often Mild Steel (Low Carbon Steel) or Stainless Steel, depending on the required corrosion resistance and strength.

-

Thickness: Typically ranges from very thin (e.g., 0.2 mm) up to a few millimeters (e.g., 3.0 mm), depending on the specific part being manufactured.

-

Grade: Specified according to international standards (e.g., IS 513 in India, or various JIS, EN, ASTM standards) to ensure the correct chemical composition and mechanical properties (like tensile strength and yield strength).

-

Surface Treatment: The final product made from the coil may receive various coatings (like galvanization, zinc plating, etc.) for added corrosion resistance.

Cr Narrow Coil discreption

-

Query successful

A CR Narrow Coil is essentially a Cold Rolled (CR) steel coil that has been processed to a smaller or "narrow" width, typically through a secondary manufacturing step called slitting.

Here is a breakdown of its description, properties, and common uses:

Description

-

CR (Cold Rolled): This refers to the manufacturing process. The steel coil is produced by further processing a hot-rolled coil at or near room temperature (below its recrystallization temperature). This process gives the steel a number of advantages over hot-rolled steel.

-

Narrow Coil/Slit Coil: The term "narrow" indicates that the original, wider CR coil (the "master coil") has been cut lengthwise into multiple narrower strips. This process is called slitting, and the resulting products are often referred to as CR Slit Coils or Narrow CR Coils.

-

Material: Usually made from Mild Steel (MS) or various grades of Stainless Steel (like the 300 series).

-

CR (Cold Rolled): This refers to the manufacturing process. The steel coil is produced by further processing a hot-rolled coil at or near room temperature (below its recrystallization temperature). This process gives the steel a number of advantages over hot-rolled steel.

-

Narrow Coil/Slit Coil: The term "narrow" indicates that the original, wider CR coil (the "master coil") has been cut lengthwise into multiple narrower strips. This process is called slitting, and the resulting products are often referred to as CR Slit Coils or Narrow CR Coils.

-

Material: Usually made from Mild Steel (MS) or various grades of Stainless Steel (like the 300 series).

Key Properties

The cold rolling process imparts specific characteristics:

-

Superior Surface Finish: It has a smooth, clean surface, which is often aesthetically pleasing (e.g., in appliance casings) and an excellent base for painting or plating.

-

Tighter Dimensional Tolerances: It offers greater precision in thickness and width compared to hot-rolled steel.

-

Increased Strength: The cold-working process increases the steels yield and tensile strength, often allowing for thinner material to be used in certain applications.

-

Better Formability: Its consistent properties and surface make it suitable for various shaping operations like stamping, deep drawing, and bending.

The cold rolling process imparts specific characteristics:

-

Superior Surface Finish: It has a smooth, clean surface, which is often aesthetically pleasing (e.g., in appliance casings) and an excellent base for painting or plating.

-

Tighter Dimensional Tolerances: It offers greater precision in thickness and width compared to hot-rolled steel.

-

Increased Strength: The cold-working process increases the steels yield and tensile strength, often allowing for thinner material to be used in certain applications.

-

Better Formability: Its consistent properties and surface make it suitable for various shaping operations like stamping, deep drawing, and bending.

Typical Specifications (Vary by Manufacturer)

-

Material Thickness: Generally ranges from very thin, such as 0.12 mm to 3.0 mm (though the range for narrow coils can be more restrictive).

-

Width: The defining characteristic. While standard CR coils can be 900mm up to 2000mm wide, narrow coils are slit to customer-specific widths, often in ranges like 20 mm up to 850 mm or as required by the application.

-

Grades: Available in various steel grades, including Commercial Steel (CS), Drawing Steel (DS), Deep Drawing Steel (DD), Extra Deep Drawing Steel (EDD), and High Strength Low Alloy (HSLA) grades.

-

Material Thickness: Generally ranges from very thin, such as 0.12 mm to 3.0 mm (though the range for narrow coils can be more restrictive).

-

Width: The defining characteristic. While standard CR coils can be 900mm up to 2000mm wide, narrow coils are slit to customer-specific widths, often in ranges like 20 mm up to 850 mm or as required by the application.

-

Grades: Available in various steel grades, including Commercial Steel (CS), Drawing Steel (DS), Deep Drawing Steel (DD), Extra Deep Drawing Steel (EDD), and High Strength Low Alloy (HSLA) grades.

Common Applications

Narrow CR Coils are widely used in manufacturing where precision, a good surface finish, and specific widths are required, including:

-

Automobile Industry: Components like brackets, small structural parts, and various trim pieces.

-

Appliance/White Goods: Parts for refrigerators, washing machines, ovens, and other household appliances.

-

Precision Tubes & Pipes: Used as the raw material for forming precision tubing.

-

Electrical: Components such as electrical panels, transformer laminations, and motor cores.

-

Furniture: Metal frames, drawer slides, and cabinet components.

-

General Engineering: Various stamped, formed, and fabricated parts.

Cr Coil For Pipe Industry discreption

-

Query successful

A Cold Rolled (CR) Coil used in the pipe industry is a flat steel product that serves as the raw material for manufacturing high-quality steel pipes and tubes, especially Electric Resistance Welded (ERW) pipes.

Here is a description of its key characteristics and role in the pipe industry:

Narrow CR Coils are widely used in manufacturing where precision, a good surface finish, and specific widths are required, including:

-

Automobile Industry: Components like brackets, small structural parts, and various trim pieces.

-

Appliance/White Goods: Parts for refrigerators, washing machines, ovens, and other household appliances.

-

Precision Tubes & Pipes: Used as the raw material for forming precision tubing.

-

Electrical: Components such as electrical panels, transformer laminations, and motor cores.

-

Furniture: Metal frames, drawer slides, and cabinet components.

-

General Engineering: Various stamped, formed, and fabricated parts.

Cr Coil For Pipe Industry discreption

-

Query successful

A Cold Rolled (CR) Coil used in the pipe industry is a flat steel product that serves as the raw material for manufacturing high-quality steel pipes and tubes, especially Electric Resistance Welded (ERW) pipes.

Here is a description of its key characteristics and role in the pipe industry:

1. Manufacturing Process

-

Cold Rolling: The CR coil is produced from a Hot Rolled (HR) coil. The HR coil is first pickled (to remove surface scale/oxide) and then passed through rollers at room temperature (below the steels recrystallization temperature).

-

Effect: This cold-working process compresses the steel, reducing its thickness and significantly improving its properties.

-

Cold Rolling: The CR coil is produced from a Hot Rolled (HR) coil. The HR coil is first pickled (to remove surface scale/oxide) and then passed through rollers at room temperature (below the steels recrystallization temperature).

-

Effect: This cold-working process compresses the steel, reducing its thickness and significantly improving its properties.

2. Key Characteristics

CR coils are preferred for pipe manufacturing where precision and surface quality are critical. They offer:

-

Superior Surface Finish: They have a much smoother, cleaner, and brighter surface compared to hot-rolled steel, which is ideal for pipes that may require plating, painting, or an aesthetic finish (e.g., in furniture).

-

Tighter Dimensional Tolerances: The cold rolling process provides excellent control over the final thickness, width, and overall dimensions. This dimensional accuracy is crucial for consistent pipe wall thickness and uniform external dimensions.

-

Enhanced Mechanical Properties: The process increases the steels strength and hardness (a process called strain hardening), making the resulting pipes stronger and more durable.

-

Good Formability: Specific grades (such as Deep Drawing or Extra Deep Drawing grades) are used to ensure the coil can be easily cut, bent, and formed into the pipe shape during the manufacturing process.

CR coils are preferred for pipe manufacturing where precision and surface quality are critical. They offer:

-

Superior Surface Finish: They have a much smoother, cleaner, and brighter surface compared to hot-rolled steel, which is ideal for pipes that may require plating, painting, or an aesthetic finish (e.g., in furniture).

-

Tighter Dimensional Tolerances: The cold rolling process provides excellent control over the final thickness, width, and overall dimensions. This dimensional accuracy is crucial for consistent pipe wall thickness and uniform external dimensions.

-

Enhanced Mechanical Properties: The process increases the steels strength and hardness (a process called strain hardening), making the resulting pipes stronger and more durable.

-

Good Formability: Specific grades (such as Deep Drawing or Extra Deep Drawing grades) are used to ensure the coil can be easily cut, bent, and formed into the pipe shape during the manufacturing process.

3. Application in Pipe Manufacturing

The CR coil is slit into narrower strips (skelp) and then fed into a pipe mill, where it is progressively formed into a cylindrical shape. The edges are then welded together using an electric resistance welding process to create the final pipe or tube.

Pipes and tubes made from CR coils are used in various applications, including:

-

Furniture: Frames for chairs, tables, and cabinets (where a smooth finish is necessary).

-

Automotive: Exhaust pipes, seating components, and structural parts.

-

Construction & Infrastructure: Non-structural and some structural applications, electrical conduits, and various utility piping.

-

Appliances: Components for home and commercial appliances.

The CR coil is slit into narrower strips (skelp) and then fed into a pipe mill, where it is progressively formed into a cylindrical shape. The edges are then welded together using an electric resistance welding process to create the final pipe or tube.

Pipes and tubes made from CR coils are used in various applications, including:

-

Furniture: Frames for chairs, tables, and cabinets (where a smooth finish is necessary).

-

Automotive: Exhaust pipes, seating components, and structural parts.

-

Construction & Infrastructure: Non-structural and some structural applications, electrical conduits, and various utility piping.

-

Appliances: Components for home and commercial appliances.

4. Typical Specifications (Examples)

Common CR coil specifications for pipe and tube manufacturing are based on standards like JIS or ASTM and can include:

Feature

Typical Specification Range

Grades (Examples)

SPCC, DC01, ST12, ASTM A1008

Thickness

0.25 mm to 2.5 mm (varies by end-use)

Surface Finish

Bright, Super Bright, Dull, or Matte

Edge Condition

Smooth Mill Edges or Trimmed Edges

CR Slit Coils discreption

-

Query successful

A CR Slit Coil is a metal product that starts as a large Cold Rolled (CR) coil and is then precisely cut, or "slit," into narrower coils (often called strips or mults) of a specific, custom width.

Here is a detailed breakdown of its description, process, and applications.

Common CR coil specifications for pipe and tube manufacturing are based on standards like JIS or ASTM and can include:

| Feature | Typical Specification Range |

| Grades (Examples) | SPCC, DC01, ST12, ASTM A1008 |

| Thickness | 0.25 mm to 2.5 mm (varies by end-use) |

| Surface Finish | Bright, Super Bright, Dull, or Matte |

| Edge Condition | Smooth Mill Edges or Trimmed Edges |

CR Slit Coils discreption

-

Query successful

A CR Slit Coil is a metal product that starts as a large Cold Rolled (CR) coil and is then precisely cut, or "slit," into narrower coils (often called strips or mults) of a specific, custom width.

Here is a detailed breakdown of its description, process, and applications.

1. Description and Characteristics

CR Slit Coils are defined by the material and the manufacturing step that creates them:

-

CR (Cold Rolled) Material: This means the steel has been rolled at or near room temperature, resulting in a product with:

-

Superior Surface Finish: It is smooth, clean, and often bright.

-

High Dimensional Accuracy: It has tight tolerances for thickness and width.

-

Enhanced Strength and Hardness: The cold-rolling process refines the materials structure, improving its mechanical properties.

-

Slit Coil (Strip): This indicates that a wider, original coil (often called a "master" or "mother" coil) has been processed on a slitting line.

-

Process: Circular rotary knives cut the wide coil lengthwise into multiple narrow strips.

-

Result: These strips are then re-wound into smaller, ready-to-use coils that meet exact width specifications.

Typical Specifications (Ranges vary by manufacturer)

Material

Thickness

Width

Surface

CR Slit Coils are defined by the material and the manufacturing step that creates them:

-

CR (Cold Rolled) Material: This means the steel has been rolled at or near room temperature, resulting in a product with:

-

Superior Surface Finish: It is smooth, clean, and often bright.

-

High Dimensional Accuracy: It has tight tolerances for thickness and width.

-

Enhanced Strength and Hardness: The cold-rolling process refines the materials structure, improving its mechanical properties.

-

-

Slit Coil (Strip): This indicates that a wider, original coil (often called a "master" or "mother" coil) has been processed on a slitting line.

-

Process: Circular rotary knives cut the wide coil lengthwise into multiple narrow strips.

-

Result: These strips are then re-wound into smaller, ready-to-use coils that meet exact width specifications.

-

| Typical Specifications (Ranges vary by manufacturer) |

| Material |

| Thickness |

| Width |

| Surface |

2. Manufacturing Process (Slitting)

The key to a CR Slit Coil is the slitting line, which performs three main functions:

-

Uncoiling: The master coil is loaded onto an uncoiler that unwinds the material.

-

Slitting: The strip passes through a slitter head where precisely spaced rotary knives cut the wide material into the required number of narrower strips. This step requires high precision to ensure clean, uniform edges with minimal burr.

-

Recoiling: The newly cut, narrower strips are individually tensioned and re-wound onto a recoiler to form the final, smaller CR Slit Coils.

The key to a CR Slit Coil is the slitting line, which performs three main functions:

-

Uncoiling: The master coil is loaded onto an uncoiler that unwinds the material.

-

Slitting: The strip passes through a slitter head where precisely spaced rotary knives cut the wide material into the required number of narrower strips. This step requires high precision to ensure clean, uniform edges with minimal burr.

-

Recoiling: The newly cut, narrower strips are individually tensioned and re-wound onto a recoiler to form the final, smaller CR Slit Coils.

3. Primary Applications

Due to their precise dimensions, smooth surface, and uniform thickness, CR Slit Coils are essential raw materials for downstream manufacturing in a wide array of industries:

-

Automotive Industry: Used for interior and exterior components, body panels, structural parts, and brackets.

-

Appliances (White Goods): Manufacturing of refrigerators, washing machine drums, air conditioner casings, and other household appliance parts.

-

Construction: Used for making channels, studs, metal doors, window frames, and specialized roofing/wall components via roll forming.

-

Electrical & Electronics: Fabrication of motor laminations, transformer cores (often using CRGO steel), enclosures, and other electronic components.

-

Metal Packaging: Used for producing cans, drums, and various metal containers.

-

General Fabrication: Used in numerous stamping, bending, and roll-forming operations that require pre-cut material with tight width tolerance.

Cold Rolled Coil discreption

-

Query successful

A Cold Rolled Coil (CRC) is a finished, flat steel product that has been processed at or near room temperature (below the steels recrystallization temperature) to improve its surface quality, dimensional accuracy, and mechanical strength.

It is typically manufactured from a hot-rolled coil, which is further processed through several stages. The final product is a long, thin sheet of steel tightly wound into a large coil.

Due to their precise dimensions, smooth surface, and uniform thickness, CR Slit Coils are essential raw materials for downstream manufacturing in a wide array of industries:

-

Automotive Industry: Used for interior and exterior components, body panels, structural parts, and brackets.

-

Appliances (White Goods): Manufacturing of refrigerators, washing machine drums, air conditioner casings, and other household appliance parts.

-

Construction: Used for making channels, studs, metal doors, window frames, and specialized roofing/wall components via roll forming.

-

Electrical & Electronics: Fabrication of motor laminations, transformer cores (often using CRGO steel), enclosures, and other electronic components.

-

Metal Packaging: Used for producing cans, drums, and various metal containers.

-

General Fabrication: Used in numerous stamping, bending, and roll-forming operations that require pre-cut material with tight width tolerance.

Cold Rolled Coil discreption

-

Query successful

A Cold Rolled Coil (CRC) is a finished, flat steel product that has been processed at or near room temperature (below the steels recrystallization temperature) to improve its surface quality, dimensional accuracy, and mechanical strength.

It is typically manufactured from a hot-rolled coil, which is further processed through several stages. The final product is a long, thin sheet of steel tightly wound into a large coil.

Key Characteristics and Properties

-

Superior Surface Finish: CR Coils have a much smoother, brighter, and cleaner surface compared to hot-rolled steel, making them ideal for painting or further coating processes.

-

Tighter Dimensional Tolerances: The cold rolling process allows for precise control over the thickness and width, resulting in high dimensional accuracy.

-

Enhanced Mechanical Properties: Cold rolling significantly increases the hardness, tensile strength, and yield strength of the steel due to work hardening (up to 20% stronger than its hot-rolled counterpart).

-

Excellent Formability and Ductility: While stronger, most common grades of annealed CRC retain good ductility, allowing them to be easily bent, stamped, and formed into complex shapes without cracking.

-

Typical Dimensions: Thickness generally ranges from 0.15 mm to 3.0 mm. Widths vary, often up to 2000 mm.

-

Superior Surface Finish: CR Coils have a much smoother, brighter, and cleaner surface compared to hot-rolled steel, making them ideal for painting or further coating processes.

-

Tighter Dimensional Tolerances: The cold rolling process allows for precise control over the thickness and width, resulting in high dimensional accuracy.

-

Enhanced Mechanical Properties: Cold rolling significantly increases the hardness, tensile strength, and yield strength of the steel due to work hardening (up to 20% stronger than its hot-rolled counterpart).

-

Excellent Formability and Ductility: While stronger, most common grades of annealed CRC retain good ductility, allowing them to be easily bent, stamped, and formed into complex shapes without cracking.

-

Typical Dimensions: Thickness generally ranges from 0.15 mm to 3.0 mm. Widths vary, often up to 2000 mm.

Manufacturing Process

The production of a Cold Rolled Coil involves several key steps after the initial hot rolling of steel into a coil (which is the starting material):

-

Pickling: The hot-rolled coil is treated with an acid solution (usually hydrochloric acid) to remove the layer of iron oxide (mill scale) from its surface.

-

Cold Rolling/Reduction: The cleaned coil is passed through a series of rollers at room temperature. This high-pressure rolling reduces the thickness of the strip to the desired gauge and improves the surface finish.

-

Electrolytic Cleaning (Optional): This step removes any rolling oils or contaminants prior to heat treatment.

-

Annealing (Heat Treatment): The coil is heated in a controlled atmosphere to a specific temperature and then slowly cooled. This process relieves internal stresses built up during cold rolling, restores ductility, and softens the steel for further forming. The final properties are often dependent on whether the coil is fully annealed (soft) or remains "full hard" (hard and brittle).

-

Skin Pass (Temper Rolling): A final, light cold-rolling pass is performed to improve the surface finish, eliminate yield point elongation (which prevents stretcher strains during forming), and ensure the final coil shape.

-

Coiling and Finishing: The finished strip is coiled for transportation and storage. It may also undergo final inspection, slitting (cutting to a narrower width), or shearing (cutting to sheets).

The production of a Cold Rolled Coil involves several key steps after the initial hot rolling of steel into a coil (which is the starting material):

-

Pickling: The hot-rolled coil is treated with an acid solution (usually hydrochloric acid) to remove the layer of iron oxide (mill scale) from its surface.

-

Cold Rolling/Reduction: The cleaned coil is passed through a series of rollers at room temperature. This high-pressure rolling reduces the thickness of the strip to the desired gauge and improves the surface finish.

-

Electrolytic Cleaning (Optional): This step removes any rolling oils or contaminants prior to heat treatment.

-

Annealing (Heat Treatment): The coil is heated in a controlled atmosphere to a specific temperature and then slowly cooled. This process relieves internal stresses built up during cold rolling, restores ductility, and softens the steel for further forming. The final properties are often dependent on whether the coil is fully annealed (soft) or remains "full hard" (hard and brittle).

-

Skin Pass (Temper Rolling): A final, light cold-rolling pass is performed to improve the surface finish, eliminate yield point elongation (which prevents stretcher strains during forming), and ensure the final coil shape.

-

Coiling and Finishing: The finished strip is coiled for transportation and storage. It may also undergo final inspection, slitting (cutting to a narrower width), or shearing (cutting to sheets).

Common Applications

CR Coils are widely used in applications where surface quality, precise dimensions, and specific mechanical properties are critical.

-

Automotive Industry: Car body panels, doors, fenders, and structural components.

-

Appliances: Outer casings for refrigerators, washing machines, ovens, air conditioning units, and other household items.

-

Construction: Metal furniture, shelving, roofing, wall panels, and structural components requiring high strength and a good finish.

-

Electrical Equipment: Electrical enclosures, cabinets, and components.

-

General Manufacturing: Pipes, tubes, and precision-stamped parts.

CR Coils are widely used in applications where surface quality, precise dimensions, and specific mechanical properties are critical.

-

Automotive Industry: Car body panels, doors, fenders, and structural components.

-

Appliances: Outer casings for refrigerators, washing machines, ovens, air conditioning units, and other household items.

-

Construction: Metal furniture, shelving, roofing, wall panels, and structural components requiring high strength and a good finish.

-

Electrical Equipment: Electrical enclosures, cabinets, and components.

-

General Manufacturing: Pipes, tubes, and precision-stamped parts.

Common Grades and Standards

Cold Rolled Coils are produced in various grades, often categorized by their mechanical properties and suitability for drawing/forming:

Grade Type

Characteristics

International Standards (Examples)

Commercial Quality (CQ)

General-purpose use, moderate forming/bending.

ASTM A1008 CS Type B, JIS G3141 SPCC, EN 10130 DC01

Drawing Quality (DQ)

Good ductility, suitable for moderate deep drawing.

ASTM A1008 DS, EN 10130 DC03

Deep Drawing Quality (DDQ)

High ductility, suitable for deep drawing operations.

ASTM A1008 DDS, EN 10130 DC04

Extra Deep Drawing Quality (EDDQ)

Very high ductility, suitable for severe deep drawing.

ASTM A1008 EDDS, EN 10130 DC06

Structural/High Strength

Higher tensile and yield strength for load-bearing parts.

ASTM A1008 HSLA, HCxxx Grades

Cold Rolled Coil discreption

-

Query successful

A Cold Rolled Coil (CRC) is a type of steel product manufactured from hot-rolled steel coil that has been further processed through a cold rolling method.

Here is a description covering its manufacturing, characteristics, and common uses:

Cold Rolled Coils are produced in various grades, often categorized by their mechanical properties and suitability for drawing/forming:

| Grade Type | Characteristics | International Standards (Examples) |

| Commercial Quality (CQ) | General-purpose use, moderate forming/bending. | ASTM A1008 CS Type B, JIS G3141 SPCC, EN 10130 DC01 |

| Drawing Quality (DQ) | Good ductility, suitable for moderate deep drawing. | ASTM A1008 DS, EN 10130 DC03 |

| Deep Drawing Quality (DDQ) | High ductility, suitable for deep drawing operations. | ASTM A1008 DDS, EN 10130 DC04 |

| Extra Deep Drawing Quality (EDDQ) | Very high ductility, suitable for severe deep drawing. | ASTM A1008 EDDS, EN 10130 DC06 |

| Structural/High Strength | Higher tensile and yield strength for load-bearing parts. | ASTM A1008 HSLA, HCxxx Grades |

Cold Rolled Coil discreption

-

Query successful

A Cold Rolled Coil (CRC) is a type of steel product manufactured from hot-rolled steel coil that has been further processed through a cold rolling method.

Here is a description covering its manufacturing, characteristics, and common uses:

1. Manufacturing Process

Cold rolling is performed at or near room temperature (below the steels recrystallization temperature), which gives it its name. The key steps are:

-

Pickling: The initial hot-rolled coil is cleaned by immersing it in an acid solution (like hydrochloric acid) to remove surface scale and oxides.

-

Cold Rolling: The cleaned, flat steel is passed through a series of rollers under high pressure. This reduces its thickness (up to 90% of the original) and significantly improves its surface finish and mechanical properties.

-

Annealing (Heat Treatment): The coil is heated in a controlled atmosphere and slowly cooled to relieve internal stresses that built up during rolling. This process increases the steels ductility (formability) and softness.

-

Skin Pass (Optional): A final, light cold rolling pass is often applied to further improve the surface finish, ensure flatness, and prevent the aging of the steel.

-

Coiling: The finished, thin, flat steel sheet is wound into a large roll or coil for storage, transport, and further processing.

Cold rolling is performed at or near room temperature (below the steels recrystallization temperature), which gives it its name. The key steps are:

-

Pickling: The initial hot-rolled coil is cleaned by immersing it in an acid solution (like hydrochloric acid) to remove surface scale and oxides.

-

Cold Rolling: The cleaned, flat steel is passed through a series of rollers under high pressure. This reduces its thickness (up to 90% of the original) and significantly improves its surface finish and mechanical properties.

-

Annealing (Heat Treatment): The coil is heated in a controlled atmosphere and slowly cooled to relieve internal stresses that built up during rolling. This process increases the steels ductility (formability) and softness.

-

Skin Pass (Optional): A final, light cold rolling pass is often applied to further improve the surface finish, ensure flatness, and prevent the aging of the steel.

-

Coiling: The finished, thin, flat steel sheet is wound into a large roll or coil for storage, transport, and further processing.

2. Characteristics

Cold Rolled Coils are prized for their superior qualities compared to hot-rolled steel:

-

Dimensional Accuracy: They have much tighter thickness tolerances and better consistency, making them ideal for precision applications.

-

Surface Finish: The surface is typically flat, smooth, clean, and bright, making it suitable for direct use, painting, or coating (like galvanizing).

-

Mechanical Properties: The cold working process increases the steels strength and hardness. However, subsequent annealing can be used to control the balance between strength and ductility (the ability to be formed without cracking).

-

Non-Shrinking/Non-Creeping: The material remains stable at ambient temperatures.

Cold Rolled Coils are prized for their superior qualities compared to hot-rolled steel:

-

Dimensional Accuracy: They have much tighter thickness tolerances and better consistency, making them ideal for precision applications.

-

Surface Finish: The surface is typically flat, smooth, clean, and bright, making it suitable for direct use, painting, or coating (like galvanizing).

-

Mechanical Properties: The cold working process increases the steels strength and hardness. However, subsequent annealing can be used to control the balance between strength and ductility (the ability to be formed without cracking).

-

Non-Shrinking/Non-Creeping: The material remains stable at ambient temperatures.

3. Common Uses

Cold Rolled Coils are essential in industries that require high strength, excellent finish, and precise dimensions:

-

Automotive: Car body panels, chassis components, seat frames, and other precision parts.

-

Appliances: Outer panels, shelves, and components for refrigerators, washing machines, ovens, etc.

-

Construction: Roofing, wall panels, metal studs, and structural components requiring a good finish.

-

Furniture: Desks, chairs, cabinets, and shelving units.

-

Electrical: Housings and components for electrical equipment and cabinets.

-

Pipes and Tubes: Used as the source material for precision pipes and tubes.

Jsw Cr Coil discreption

-

Query successful

JSWs Cold Rolled Coil (CR Coil), often referred to as Cold Rolled Closed Annealed (CRCA) Coil, is a high-quality flat steel product known for its superior surface finish, excellent formability, and precise dimensional accuracy.

It is manufactured from hot-rolled steel coil that is processed further at or near room temperature in JSWs state-of-the-art Cold Rolling Mills.

Cold Rolled Coils are essential in industries that require high strength, excellent finish, and precise dimensions:

-

Automotive: Car body panels, chassis components, seat frames, and other precision parts.

-

Appliances: Outer panels, shelves, and components for refrigerators, washing machines, ovens, etc.

-

Construction: Roofing, wall panels, metal studs, and structural components requiring a good finish.

-

Furniture: Desks, chairs, cabinets, and shelving units.

-

Electrical: Housings and components for electrical equipment and cabinets.

-

Pipes and Tubes: Used as the source material for precision pipes and tubes.

Jsw Cr Coil discreption

-

Query successful

JSWs Cold Rolled Coil (CR Coil), often referred to as Cold Rolled Closed Annealed (CRCA) Coil, is a high-quality flat steel product known for its superior surface finish, excellent formability, and precise dimensional accuracy.

It is manufactured from hot-rolled steel coil that is processed further at or near room temperature in JSWs state-of-the-art Cold Rolling Mills.

Key Characteristics and Features

Feature

Description

Manufacturing

Produced using advanced technology like the Pickling Line Tandem Cold Mill (PLTCM) and Continuous Annealing Line (CAL) to ensure consistent quality and mechanical properties.

Surface Finish

Features a smooth, bright, and clean surface, making it ideal for direct use, painting, and coating processes (like galvanizing). The finish is consistent for superior aesthetic appeal.

Dimensional Accuracy

The cold rolling process provides tight dimensional tolerances and excellent strip flatness, essential for precision engineering and mass production.

Mechanical Properties

Available in a wide range of grades to suit different strength and forming requirements, from soft drawing quality to high-strength structural grades.

Product Range

Typically available in thicknesses ranging from 0.35 mm to 3.2 mm and widths up to 1870 mm (reportedly the widest Cold Rolling Mill for automotive steel in India).

| Feature | Description |

| Manufacturing | Produced using advanced technology like the Pickling Line Tandem Cold Mill (PLTCM) and Continuous Annealing Line (CAL) to ensure consistent quality and mechanical properties. |

| Surface Finish | Features a smooth, bright, and clean surface, making it ideal for direct use, painting, and coating processes (like galvanizing). The finish is consistent for superior aesthetic appeal. |

| Dimensional Accuracy | The cold rolling process provides tight dimensional tolerances and excellent strip flatness, essential for precision engineering and mass production. |

| Mechanical Properties | Available in a wide range of grades to suit different strength and forming requirements, from soft drawing quality to high-strength structural grades. |

| Product Range | Typically available in thicknesses ranging from 0.35 mm to 3.2 mm and widths up to 1870 mm (reportedly the widest Cold Rolling Mill for automotive steel in India). |

Common Grades and Applications

JSWs CRCA Coils are manufactured in various grades to cater to specific industry needs, including:

JSWs CRCA Coils are manufactured in various grades to cater to specific industry needs, including:

Common Grades

-

Commercial Quality (CQ)

-

Drawing Quality (DQ)

-

Deep Drawing Quality (DDQ)

-

Extra Deep Drawing Quality (EDDQ)

-

Interstitial Free (IF) Steels

-

High Strength Steels (HSS), including Bake Hardening and Dual Phase grades, with tensile strengths up to 980 MPa.

-

Commercial Quality (CQ)

-

Drawing Quality (DQ)

-

Deep Drawing Quality (DDQ)

-

Extra Deep Drawing Quality (EDDQ)

-

Interstitial Free (IF) Steels

-

High Strength Steels (HSS), including Bake Hardening and Dual Phase grades, with tensile strengths up to 980 MPa.

Key Applications

CR Coils are predominantly used in industries requiring high-precision and superior surface quality:

-

Automotive Industry: Car body panels (doors, bonnets, fenders), chassis components, and interior parts, especially those requiring high formability.

-

Consumer Durables (White Goods): Outer panels and components for appliances like refrigerators, washing machines, and air conditioners.

-

General Engineering: Components for electrical panels, furniture (cabinets, lockers), metal storage shelves, and precision-formed sections.

-

Pipes and Tubes: Used as the base material for manufacturing welded tubes and pipes.

-

Packaging: Drums and barrels.

Stamping CR Coils discreption

-

Query successful

The term "Stamping CR Coils" refers to Cold Rolled (CR) Steel Coils that are specifically selected and manufactured for use in metal stamping or deep drawing processes.

Stamping is a high-volume, precision manufacturing process where a flat sheet of metal (the coil) is placed in a stamping press, and a tool (the die) is used to transform it into a complex, three-dimensional shape through techniques like punching, coining, blanking, bending, and deep drawing.

Here is a description of the material and its key requirements for stamping:

CR Coils are predominantly used in industries requiring high-precision and superior surface quality:

-

Automotive Industry: Car body panels (doors, bonnets, fenders), chassis components, and interior parts, especially those requiring high formability.

-

Consumer Durables (White Goods): Outer panels and components for appliances like refrigerators, washing machines, and air conditioners.

-

General Engineering: Components for electrical panels, furniture (cabinets, lockers), metal storage shelves, and precision-formed sections.

-

Pipes and Tubes: Used as the base material for manufacturing welded tubes and pipes.

-

Packaging: Drums and barrels.

Stamping CR Coils discreption

-

Query successful

The term "Stamping CR Coils" refers to Cold Rolled (CR) Steel Coils that are specifically selected and manufactured for use in metal stamping or deep drawing processes.

Stamping is a high-volume, precision manufacturing process where a flat sheet of metal (the coil) is placed in a stamping press, and a tool (the die) is used to transform it into a complex, three-dimensional shape through techniques like punching, coining, blanking, bending, and deep drawing.

Here is a description of the material and its key requirements for stamping:

1. Description of the Material

-

Base Material: Cold Rolled Steel Coil (often CRCA - Cold Rolled Closed Annealed).

-

Manufacturing: The hot-rolled coil is processed further at room temperature (cold reduction) to achieve tighter dimensional control and a better surface. Crucially, for stamping, the coil undergoes Annealing (heat treatment) to soften the steel and restore its ductility (the ability to be deformed without fracturing).

-

Form: Supplied as large, continuous coils which are unrolled and fed directly into high-speed stamping presses.

-

Base Material: Cold Rolled Steel Coil (often CRCA - Cold Rolled Closed Annealed).

-

Manufacturing: The hot-rolled coil is processed further at room temperature (cold reduction) to achieve tighter dimensional control and a better surface. Crucially, for stamping, the coil undergoes Annealing (heat treatment) to soften the steel and restore its ductility (the ability to be deformed without fracturing).

-

Form: Supplied as large, continuous coils which are unrolled and fed directly into high-speed stamping presses.

2. Key Requirements for Stamping Coils

For a CR coil to be suitable for stamping, especially for complex or deep-drawn parts (like automotive body panels or appliance casings), it must possess specific characteristics:

Property

Requirement for Stamping

Why it is important

Ductility/Formability

Very High. This is the most critical factor.

Allows the coil to be bent, stretched, and drawn into complex shapes without cracking, tearing, or developing stretcher strains (Lders lines).

Yield Strength (YS)

Low to Moderate. Lower YS means the material is softer and easier to permanently deform with less press force.

Facilitates plastic deformation (forming the new shape) rather than elastic deformation (spring-back).

Surface Finish

Smooth, Clean, and Uniform. Often a matte or smooth finish is specified.

Essential for applications that will be painted or coated (e.g., automotive, appliances). A clean surface prevents tool wear and ensures paint adhesion.

Dimensional Tolerance

Tight/Precise. Especially consistent thickness across the strip.

Guarantees consistent material volume for the stamped part, prevents wrinkling, and ensures high precision for assembled components.

Earing/Anisotropy

Low Earing / High Isotropism (for deep drawing grades).

Ensures a uniform wall thickness and height around the perimeter of a drawn cup or part, minimizing material waste.

For a CR coil to be suitable for stamping, especially for complex or deep-drawn parts (like automotive body panels or appliance casings), it must possess specific characteristics:

| Property | Requirement for Stamping | Why it is important |

| Ductility/Formability | Very High. This is the most critical factor. | Allows the coil to be bent, stretched, and drawn into complex shapes without cracking, tearing, or developing stretcher strains (Lders lines). |

| Yield Strength (YS) | Low to Moderate. Lower YS means the material is softer and easier to permanently deform with less press force. | Facilitates plastic deformation (forming the new shape) rather than elastic deformation (spring-back). |

| Surface Finish | Smooth, Clean, and Uniform. Often a matte or smooth finish is specified. | Essential for applications that will be painted or coated (e.g., automotive, appliances). A clean surface prevents tool wear and ensures paint adhesion. |

| Dimensional Tolerance | Tight/Precise. Especially consistent thickness across the strip. | Guarantees consistent material volume for the stamped part, prevents wrinkling, and ensures high precision for assembled components. |

| Earing/Anisotropy | Low Earing / High Isotropism (for deep drawing grades). | Ensures a uniform wall thickness and height around the perimeter of a drawn cup or part, minimizing material waste. |

3. Common Stamping Grades

CR Coils are classified by their ability to be formed. The grades below are common industry standards (e.g., BIS, EN, JIS) used for stamping applications:

Grade Classification

Stamping Requirement

Application Example

Commercial Quality (CQ / CR1 / DC01)

Simple Bending/Forming

Flat parts, simple brackets, construction components.

Drawing Quality (DQ / CR2 / DC03)

Moderate Forming/Shallow Drawing

Appliance shells, shallow auto parts, general-purpose stampings.

Deep Drawing Quality (DDQ / CR3 / DC04)

High Forming/Deep Drawing

Automotive door panels, intricate appliance components.

Extra Deep Drawing Quality (EDDQ / CR4 / DC05)

Very High Forming/Complex Deep Drawing

Deeply drawn components like oil pans, complex fenders.

Interstitial Free (IF / CR5 / DC06)

Highest Formability/Ultra-Deep Drawing

Critical, complex automotive body panels requiring maximum stretch.

In summary, Stamping CR Coils are specifically annealed to be soft and ductile, offering a combination of high precision and excellent formability necessary for mass-producing intricate metal components.

Mild Steel CR Coils discreption

-

Query successful

Mild Steel Cold Rolled (CR) Coils are a flat steel product processed at or near room temperature. This process refines the materials properties, making it a highly desirable material for applications requiring superior finish, precision, and formability.

Here is a detailed description:

CR Coils are classified by their ability to be formed. The grades below are common industry standards (e.g., BIS, EN, JIS) used for stamping applications:

| Grade Classification | Stamping Requirement | Application Example |

| Commercial Quality (CQ / CR1 / DC01) | Simple Bending/Forming | Flat parts, simple brackets, construction components. |

| Drawing Quality (DQ / CR2 / DC03) | Moderate Forming/Shallow Drawing | Appliance shells, shallow auto parts, general-purpose stampings. |

| Deep Drawing Quality (DDQ / CR3 / DC04) | High Forming/Deep Drawing | Automotive door panels, intricate appliance components. |

| Extra Deep Drawing Quality (EDDQ / CR4 / DC05) | Very High Forming/Complex Deep Drawing | Deeply drawn components like oil pans, complex fenders. |

| Interstitial Free (IF / CR5 / DC06) | Highest Formability/Ultra-Deep Drawing | Critical, complex automotive body panels requiring maximum stretch. |

In summary, Stamping CR Coils are specifically annealed to be soft and ductile, offering a combination of high precision and excellent formability necessary for mass-producing intricate metal components.

Mild Steel CR Coils discreption

-

Query successful

Mild Steel Cold Rolled (CR) Coils are a flat steel product processed at or near room temperature. This process refines the materials properties, making it a highly desirable material for applications requiring superior finish, precision, and formability.

Here is a detailed description:

1. Manufacturing Process

Mild steel, initially produced as Hot Rolled (HR) coils, undergoes further processing:

-

Pickling: The hot rolled coil is cleaned, typically with acid, to remove surface scale (iron oxide).

-

Cold Rolling: The pickled coil is then passed through a series of rollers at room temperature (below the steels recrystallization temperature). This reduces its thickness, increases its strength and hardness, and improves dimensional accuracy.

-

Annealing (Optional but Common): The cold-rolled coil often undergoes heat treatment (annealing) to reduce internal stresses, improve ductility (ability to be formed), and soften the material.

-

Skin Pass (Optional): A final, light cold rolling to improve surface finish, remove minor defects, and control mechanical properties like yield point elongation.

-

Oiling: The finished coil is usually coated with a thin layer of oil to prevent rust and corrosion during storage and transport.

Mild steel, initially produced as Hot Rolled (HR) coils, undergoes further processing:

-

Pickling: The hot rolled coil is cleaned, typically with acid, to remove surface scale (iron oxide).

-

Cold Rolling: The pickled coil is then passed through a series of rollers at room temperature (below the steels recrystallization temperature). This reduces its thickness, increases its strength and hardness, and improves dimensional accuracy.

-

Annealing (Optional but Common): The cold-rolled coil often undergoes heat treatment (annealing) to reduce internal stresses, improve ductility (ability to be formed), and soften the material.

-

Skin Pass (Optional): A final, light cold rolling to improve surface finish, remove minor defects, and control mechanical properties like yield point elongation.

-

Oiling: The finished coil is usually coated with a thin layer of oil to prevent rust and corrosion during storage and transport.

2. Key Properties

Mild Steel CR Coils are known for:

-

Superior Surface Finish: They have a smoother, cleaner, and brighter surface compared to hot-rolled steel, making them ideal for painting, plating, and other surface treatments.

-

Excellent Dimensional Accuracy: They have much tighter thickness tolerances and better uniformity.

-

Enhanced Mechanical Properties: The cold rolling process increases the steels tensile strength and yield strength (work hardening).

-

Good Formability/Ductility: Depending on the grade (especially annealed grades), they have good formability, which is essential for bending, stamping, and deep drawing operations.

-

Low Carbon Content: As mild steel, the low carbon content contributes to their good weldability.

Mild Steel CR Coils are known for:

-

Superior Surface Finish: They have a smoother, cleaner, and brighter surface compared to hot-rolled steel, making them ideal for painting, plating, and other surface treatments.

-

Excellent Dimensional Accuracy: They have much tighter thickness tolerances and better uniformity.

-

Enhanced Mechanical Properties: The cold rolling process increases the steels tensile strength and yield strength (work hardening).

-

Good Formability/Ductility: Depending on the grade (especially annealed grades), they have good formability, which is essential for bending, stamping, and deep drawing operations.

-

Low Carbon Content: As mild steel, the low carbon content contributes to their good weldability.

3. Common Grades and Standards

The grade defines the materials mechanical properties, particularly its formability. Common grades and standards include:

Grade Type

Designation (Example Standards)

Primary Characteristic

Commercial Quality (CQ)

IS 513 CR1, ASTM A1008 CS

General forming and mild bending applications.

Drawing Quality (DQ)

IS 513 CR2, ASTM A1008 DS

Suitable for deeper drawing applications.

Deep Drawing Quality (DDQ)

IS 513 CR3, ASTM A1008 DDS

Good for parts requiring more severe forming.

Extra Deep Drawing Quality (EDDQ)

IS 513 CR4, ASTM A1008 EDDS

Excellent for very deep drawing applications, like complex auto body parts.

Full Hard (FH)

IS 513 CR0

Maximum hardness from cold rolling, not annealed, with limited ductility.

The grade defines the materials mechanical properties, particularly its formability. Common grades and standards include:

| Grade Type | Designation (Example Standards) | Primary Characteristic |

| Commercial Quality (CQ) | IS 513 CR1, ASTM A1008 CS | General forming and mild bending applications. |

| Drawing Quality (DQ) | IS 513 CR2, ASTM A1008 DS | Suitable for deeper drawing applications. |

| Deep Drawing Quality (DDQ) | IS 513 CR3, ASTM A1008 DDS | Good for parts requiring more severe forming. |

| Extra Deep Drawing Quality (EDDQ) | IS 513 CR4, ASTM A1008 EDDS | Excellent for very deep drawing applications, like complex auto body parts. |

| Full Hard (FH) | IS 513 CR0 | Maximum hardness from cold rolling, not annealed, with limited ductility. |

4. Typical Applications

The combination of a clean finish, precise dimensions, and good formability makes Mild Steel CR Coils suitable for a wide range of industries:

-

Automotive: Car body panels, doors, fenders, chassis components.

-

Home Appliances (White Goods): Refrigerators, washing machines, ovens, air conditioner casings.

-

Furniture: Metal cabinets, desks, shelving units.

-

Construction: Metal studs, roof panels, window frames.

-

Piping & Tubing: Precision tubes and pipes.

-

General Engineering: Electrical panels, drums, barrels, and various stamped or drawn components.

Tata Hr Coil discreption

-

Query successful

Tata HR Coils, primarily branded as Tata Astrum in India, are Hot Rolled (HR) Steel Coils manufactured by Tata Steel. They are a versatile, high-quality steel product known for strength, durability, and formability, making them suitable for heavy-duty applications.

The combination of a clean finish, precise dimensions, and good formability makes Mild Steel CR Coils suitable for a wide range of industries:

-

Automotive: Car body panels, doors, fenders, chassis components.

-

Home Appliances (White Goods): Refrigerators, washing machines, ovens, air conditioner casings.

-

Furniture: Metal cabinets, desks, shelving units.

-

Construction: Metal studs, roof panels, window frames.

-

Piping & Tubing: Precision tubes and pipes.

-

General Engineering: Electrical panels, drums, barrels, and various stamped or drawn components.

Tata Hr Coil discreption

-

Query successful

Tata HR Coils, primarily branded as Tata Astrum in India, are Hot Rolled (HR) Steel Coils manufactured by Tata Steel. They are a versatile, high-quality steel product known for strength, durability, and formability, making them suitable for heavy-duty applications.

Product Description and Manufacturing

-

Product Type: Hot Rolled (HR) Steel Coil, typically made from Carbon Steel.

-

Manufacturing Process: Steel slabs (or transfer bars in some mills) are heated to high temperatures (over 1700F or 927C) and then rolled in a Hot Strip Mill (HSM) to the desired thickness and width. The subsequent controlled cooling ensures the product attains the required mechanical properties.

-

Brand Name (India): The hot rolled sheets and coils from Tata Steel are often marketed under the brand name Tata Astrum.

-

Dimensions (Typical Range):

-

Thickness: Generally ranges from 1.6 mm to 25 mm.

-

Width: Typically ranges from 800 mm to 2050 mm (varying by thickness and plant).

-

Coil Finish: Available in:

-

Non-pickled (Dry): The surface retains the mill scale, an iron oxide film formed during the hot rolling process.

-

Pickled and Oiled (HRPO): The mill scale is removed using an acid bath (pickling) for a cleaner, uniform surface, and then oiled to prevent rust.

-

Skin Pass, Pickled & Oiled (HRSPO): An additional process to improve surface smoothness, thickness uniformity, and minor mechanical property corrections.

-

Product Type: Hot Rolled (HR) Steel Coil, typically made from Carbon Steel.

-

Manufacturing Process: Steel slabs (or transfer bars in some mills) are heated to high temperatures (over 1700F or 927C) and then rolled in a Hot Strip Mill (HSM) to the desired thickness and width. The subsequent controlled cooling ensures the product attains the required mechanical properties.

-

Brand Name (India): The hot rolled sheets and coils from Tata Steel are often marketed under the brand name Tata Astrum.

-

Dimensions (Typical Range):

-

Thickness: Generally ranges from 1.6 mm to 25 mm.

-

Width: Typically ranges from 800 mm to 2050 mm (varying by thickness and plant).

-

-

Coil Finish: Available in:

-

Non-pickled (Dry): The surface retains the mill scale, an iron oxide film formed during the hot rolling process.

-

Pickled and Oiled (HRPO): The mill scale is removed using an acid bath (pickling) for a cleaner, uniform surface, and then oiled to prevent rust.

-

Skin Pass, Pickled & Oiled (HRSPO): An additional process to improve surface smoothness, thickness uniformity, and minor mechanical property corrections.

-

Common Grades and Standards

Tata HR Coils are produced in numerous grades to meet various international and national standards, including those for structural, forming, and high-strength applications.

Category

Typical Grades (Examples)

Indian Standards (IS)

IS 2062 (Various grades like E250, E350), IS 1079 (O, D, DD, EDD), IS 5986

European Standards (EN)

EN 10025 (Structural grades like S235, S275, S355), EN 10149 (High-Strength grades like S460MC)

Other International

ASTM A36/A570, JIS G3101 SS400 (Structural) and JIS G3131 SPHC (Forming)

-

Key Properties: Hot Rolled Coils generally offer excellent weldability, yield strength, tensile strength, ductility, and toughness. They are often preferred over Cold Rolled Coils when dimensional precision and surface finish are secondary to strength and cost.

Tata HR Coils are produced in numerous grades to meet various international and national standards, including those for structural, forming, and high-strength applications.

| Category | Typical Grades (Examples) |

| Indian Standards (IS) | IS 2062 (Various grades like E250, E350), IS 1079 (O, D, DD, EDD), IS 5986 |

| European Standards (EN) | EN 10025 (Structural grades like S235, S275, S355), EN 10149 (High-Strength grades like S460MC) |

| Other International | ASTM A36/A570, JIS G3101 SS400 (Structural) and JIS G3131 SPHC (Forming) |

-

Key Properties: Hot Rolled Coils generally offer excellent weldability, yield strength, tensile strength, ductility, and toughness. They are often preferred over Cold Rolled Coils when dimensional precision and surface finish are secondary to strength and cost.

Major Applications

Tata HR Coils are widely used in critical sectors for manufacturing and construction:

-

Automotive Industry: Chassis components, wheel rims, structural parts, and tubes.

-

Construction & Infrastructure: Structural steel for buildings, bridges, and general fabrication (beams, columns, frames).

-

Pipes and Tubes: Manufacturing welded and seamless pipes for oil, gas, and water transportation.

-

Heavy Engineering: Cranes, earth-moving vehicles, industrial equipment, and heavy machinery.

-

Other Applications: Boiler and pressure vessels, railway components, transmission towers, and general sheet metal components.

Sail Hr Coil discreption

-

Query successful

SAIL (Steel Authority of India Limited) Hot Rolled (HR) Coils are a fundamental steel product produced by rolling steel slabs at high temperatures, which gives them specific characteristics, properties, and applications.

Here is a general description, often based on products from SAILs major plants like Bokaro Steel Plant:

Tata HR Coils are widely used in critical sectors for manufacturing and construction:

-

Automotive Industry: Chassis components, wheel rims, structural parts, and tubes.

-

Construction & Infrastructure: Structural steel for buildings, bridges, and general fabrication (beams, columns, frames).

-

Pipes and Tubes: Manufacturing welded and seamless pipes for oil, gas, and water transportation.

-

Heavy Engineering: Cranes, earth-moving vehicles, industrial equipment, and heavy machinery.

-

Other Applications: Boiler and pressure vessels, railway components, transmission towers, and general sheet metal components.

Sail Hr Coil discreption

-

Query successful

SAIL (Steel Authority of India Limited) Hot Rolled (HR) Coils are a fundamental steel product produced by rolling steel slabs at high temperatures, which gives them specific characteristics, properties, and applications.

Here is a general description, often based on products from SAILs major plants like Bokaro Steel Plant:

1. Manufacturing Process

-

Hot Rolling: The steel is heated above its recrystallization temperature (typically over 927C or 1700F) and passed through a series of rollers to achieve the desired thickness.

-

Resulting Finish: The product typically has a rougher surface finish with a characteristic blue-grey mill scale (iron oxide) on the surface, due to the high-temperature processing.

-

Hot Rolling: The steel is heated above its recrystallization temperature (typically over 927C or 1700F) and passed through a series of rollers to achieve the desired thickness.

-

Resulting Finish: The product typically has a rougher surface finish with a characteristic blue-grey mill scale (iron oxide) on the surface, due to the high-temperature processing.

Conversation with Gemini

-

Cr Fastner Coil discreption

-

Query successful

The term "CR Fastener Coil" most likely refers to Cold Rolled (CR) steel coil that is specifically used in the manufacturing of fasteners or related components.

Here is a general description, focusing on the "Cold Rolled Coil" aspect, as this is the raw material:

-

Cr Fastner Coil discreption

-

Query successful

The term "CR Fastener Coil" most likely refers to Cold Rolled (CR) steel coil that is specifically used in the manufacturing of fasteners or related components.

Here is a general description, focusing on the "Cold Rolled Coil" aspect, as this is the raw material:

-

1. What a CR Coil Is (Cold Rolled Coil)

-

-

Manufacturing Process: CR (Cold Rolled) coils are produced from hot-rolled steel that is further processed at or near room temperature. This involves passing the steel through a series of high-precision rollers (cold rolling process).

-

Resulting Properties (compared to hot-rolled steel):

-

Superior Surface Finish: They have a smooth, clean surface, ideal for applications requiring a high-quality finish, like painting or plating (common for many fasteners).

-

Tighter Dimensional Accuracy: Cold rolling provides excellent control over thickness and flatness, resulting in very precise dimensions.

-

Increased Strength: The process increases the steels tensile and yield strength, making the material stronger and harder.

-

Improved Formability/Ductility (if annealed): Depending on the final processing (such as annealing, which results in CRCA - Cold Rolled Closed Annealed), the material can also have excellent ductility and formability, which is essential for stamping, bending, or drawing into complex shapes like certain fasteners.

-

-

Manufacturing Process: CR (Cold Rolled) coils are produced from hot-rolled steel that is further processed at or near room temperature. This involves passing the steel through a series of high-precision rollers (cold rolling process).

-

Resulting Properties (compared to hot-rolled steel):

-

Superior Surface Finish: They have a smooth, clean surface, ideal for applications requiring a high-quality finish, like painting or plating (common for many fasteners).

-

Tighter Dimensional Accuracy: Cold rolling provides excellent control over thickness and flatness, resulting in very precise dimensions.

-

Increased Strength: The process increases the steels tensile and yield strength, making the material stronger and harder.

-

Improved Formability/Ductility (if annealed): Depending on the final processing (such as annealing, which results in CRCA - Cold Rolled Closed Annealed), the material can also have excellent ductility and formability, which is essential for stamping, bending, or drawing into complex shapes like certain fasteners.

-

-

2. "Fastener Coil" Application

-

When specified as a "Fastener Coil," the Cold Rolled steel coil is intended for use as the raw material for:

-

Stamping and forming components of fasteners (such as washers, clips, brackets, etc.).

-

Producing threaded inserts (often helical coil inserts) used to repair or reinforce threads in softer materials. These inserts are often cold-formed from high-strength stainless steel wire, which is a form of cold-rolled material.

-

Manufacturing other small metal parts or components within a fastening or joining system that require precision and a high-quality surface finish.

-

When specified as a "Fastener Coil," the Cold Rolled steel coil is intended for use as the raw material for:

-

Stamping and forming components of fasteners (such as washers, clips, brackets, etc.).

-

Producing threaded inserts (often helical coil inserts) used to repair or reinforce threads in softer materials. These inserts are often cold-formed from high-strength stainless steel wire, which is a form of cold-rolled material.

-

Manufacturing other small metal parts or components within a fastening or joining system that require precision and a high-quality surface finish.

-

3. Typical Specifications (Can vary widely)

-

Specifications depend heavily on the final fastener product, but generally include:

-

Material: Often Mild Steel (Low Carbon Steel) or Stainless Steel, depending on the required corrosion resistance and strength.

-

Thickness: Typically ranges from very thin (e.g., 0.2 mm) up to a few millimeters (e.g., 3.0 mm), depending on the specific part being manufactured.

-

Grade: Specified according to international standards (e.g., IS 513 in India, or various JIS, EN, ASTM standards) to ensure the correct chemical composition and mechanical properties (like tensile strength and yield strength).

-

Surface Treatment: The final product made from the coil may receive various coatings (like galvanization, zinc plating, etc.) for added corrosion resistance.

Cr Narrow Coil discreption

-

Query successful

A CR Narrow Coil is essentially a Cold Rolled (CR) steel coil that has been processed to a smaller or "narrow" width, typically through a secondary manufacturing step called slitting.

Here is a breakdown of its description, properties, and common uses:

-

Specifications depend heavily on the final fastener product, but generally include:

-

Material: Often Mild Steel (Low Carbon Steel) or Stainless Steel, depending on the required corrosion resistance and strength.

-

Thickness: Typically ranges from very thin (e.g., 0.2 mm) up to a few millimeters (e.g., 3.0 mm), depending on the specific part being manufactured.

-

Grade: Specified according to international standards (e.g., IS 513 in India, or various JIS, EN, ASTM standards) to ensure the correct chemical composition and mechanical properties (like tensile strength and yield strength).

-

Surface Treatment: The final product made from the coil may receive various coatings (like galvanization, zinc plating, etc.) for added corrosion resistance.

Cr Narrow Coil discreption

-

Query successful

A CR Narrow Coil is essentially a Cold Rolled (CR) steel coil that has been processed to a smaller or "narrow" width, typically through a secondary manufacturing step called slitting.

Here is a breakdown of its description, properties, and common uses:

-

Description

-

-

CR (Cold Rolled): This refers to the manufacturing process. The steel coil is produced by further processing a hot-rolled coil at or near room temperature (below its recrystallization temperature). This process gives the steel a number of advantages over hot-rolled steel.

-

Narrow Coil/Slit Coil: The term "narrow" indicates that the original, wider CR coil (the "master coil") has been cut lengthwise into multiple narrower strips. This process is called slitting, and the resulting products are often referred to as CR Slit Coils or Narrow CR Coils.

-

Material: Usually made from Mild Steel (MS) or various grades of Stainless Steel (like the 300 series).

-

-

CR (Cold Rolled): This refers to the manufacturing process. The steel coil is produced by further processing a hot-rolled coil at or near room temperature (below its recrystallization temperature). This process gives the steel a number of advantages over hot-rolled steel.

-

Narrow Coil/Slit Coil: The term "narrow" indicates that the original, wider CR coil (the "master coil") has been cut lengthwise into multiple narrower strips. This process is called slitting, and the resulting products are often referred to as CR Slit Coils or Narrow CR Coils.

-

Material: Usually made from Mild Steel (MS) or various grades of Stainless Steel (like the 300 series).

-

Key Properties

-

The cold rolling process imparts specific characteristics:

-

Superior Surface Finish: It has a smooth, clean surface, which is often aesthetically pleasing (e.g., in appliance casings) and an excellent base for painting or plating.

-

Tighter Dimensional Tolerances: It offers greater precision in thickness and width compared to hot-rolled steel.

-

Increased Strength: The cold-working process increases the steels yield and tensile strength, often allowing for thinner material to be used in certain applications.

-

Better Formability: Its consistent properties and surface make it suitable for various shaping operations like stamping, deep drawing, and bending.

-

The cold rolling process imparts specific characteristics:

-

Superior Surface Finish: It has a smooth, clean surface, which is often aesthetically pleasing (e.g., in appliance casings) and an excellent base for painting or plating.

-

Tighter Dimensional Tolerances: It offers greater precision in thickness and width compared to hot-rolled steel.

-

Increased Strength: The cold-working process increases the steels yield and tensile strength, often allowing for thinner material to be used in certain applications.

-

Better Formability: Its consistent properties and surface make it suitable for various shaping operations like stamping, deep drawing, and bending.

-

Typical Specifications (Vary by Manufacturer)

-

-

Material Thickness: Generally ranges from very thin, such as 0.12 mm to 3.0 mm (though the range for narrow coils can be more restrictive).

-

Width: The defining characteristic. While standard CR coils can be 900mm up to 2000mm wide, narrow coils are slit to customer-specific widths, often in ranges like 20 mm up to 850 mm or as required by the application.

-

Grades: Available in various steel grades, including Commercial Steel (CS), Drawing Steel (DS), Deep Drawing Steel (DD), Extra Deep Drawing Steel (EDD), and High Strength Low Alloy (HSLA) grades.

-

-

Material Thickness: Generally ranges from very thin, such as 0.12 mm to 3.0 mm (though the range for narrow coils can be more restrictive).

-

Width: The defining characteristic. While standard CR coils can be 900mm up to 2000mm wide, narrow coils are slit to customer-specific widths, often in ranges like 20 mm up to 850 mm or as required by the application.

-

Grades: Available in various steel grades, including Commercial Steel (CS), Drawing Steel (DS), Deep Drawing Steel (DD), Extra Deep Drawing Steel (EDD), and High Strength Low Alloy (HSLA) grades.

-

Common Applications

-

Narrow CR Coils are widely used in manufacturing where precision, a good surface finish, and specific widths are required, including:

-

Automobile Industry: Components like brackets, small structural parts, and various trim pieces.

-

Appliance/White Goods: Parts for refrigerators, washing machines, ovens, and other household appliances.

-

Precision Tubes & Pipes: Used as the raw material for forming precision tubing.

-

Electrical: Components such as electrical panels, transformer laminations, and motor cores.

-

Furniture: Metal frames, drawer slides, and cabinet components.