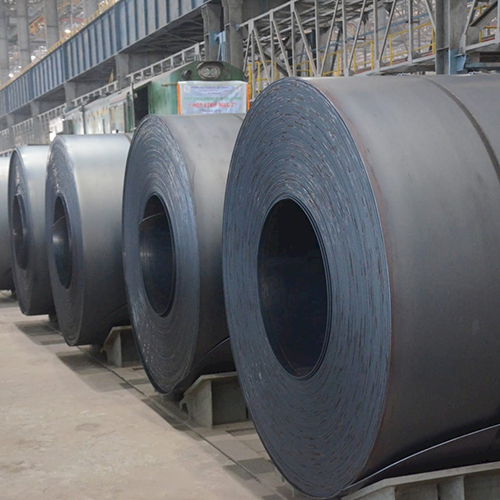

HR Slit Coils

Product Details:

- Usage Industrial

- Material Steel

- Product Type HR Slit Coils

- Grade D

- Color Silver

- Warranty 1 Year

- Click to View more

HR Slit Coils Price And Quantity

- 48 INR/Kilograms

- 2 Ton

HR Slit Coils Product Specifications

- HR Slit Coils

- Silver

- 1 Year

- Steel

- D

- Industrial

HR Slit Coils Trade Information

- 100 Ton Per Month

- 2 Days

- All India

Product Description

HR Slit Coils are a type of Hot Rolled (HR) steel coil that has been processed by slitting (longitudinally cutting) into narrower strips to meet specific width requirements. They are a fundamental product in the steel industry, offering a balance of strength, formability, and cost-effectiveness for various manufacturing and construction applications.

Key Components and Production Process

HR Slit Coils are defined by their base material and the secondary process they undergo:

-

Hot Rolled (HR) Steel Coil: This is the starting material. Its produced by heating steel slabs above their recrystallization temperature (typically over 1,700F or 927C) and then rolling them into large, continuous coils.

-

Characteristics of HR Steel: It is generally known for its high strength-to-weight ratio, good ductility, and lower cost compared to cold-rolled steel. The surface typically has a rough, scaly finish (mill scale) due to the high-temperature processing. Pickling and oiling (HRPO) can be performed to remove the scale and improve the surface for certain applications.

-

-

Slitting: This is a precision metal processing technique where the wide master coil (the original HR coil) is unwound and passed through a slitting machine. This machine uses a series of circular rotary blades to cut the coil lengthwise into multiple narrower strips, or slit coils, according to the customers exact width specifications.

-

Result: The slitting process ensures high dimensional accuracy in width and often provides a smoother edge with minimal burrs compared to other cutting methods. The slit coils are then recoiled for shipping.

-

Specifications and Properties

Specifications for HR Slit Coils vary based on the required final use, but typically include:

-

Material Grades: Available in various grades, such as commercial quality (CQ), structural quality (SQ), and different High-Strength Low-Alloy (HSLA) grades, including those for automotive applications (e.g., E160 to E450).

-

Thickness Range: Commonly available in a wide range, such as 1.2 mm to over 25 mm.

-

Width: The key customized dimension, typically ranging from very narrow strips up to around 500 mm or more, depending on the slitting equipments capacity and the final products requirement.

-

Tolerances: Slit coils are produced with tight tolerances, especially on the width and thickness, to ensure consistency for high-speed manufacturing processes.

Grade D Steel Excellence

Crafted from Grade D steel, our HR slit coils deliver superior performance for rigorous industrial requirements. Grade D assures strength and toughness, making these coils suitable for heavy-duty applications in various sectors including automotive, construction, and machinery manufacturing. Trust in the consistent material quality for your core processes.

Warranty Assurance & Support

We stand behind our product with a comprehensive 1-year warranty. This coverage guarantees that any manufacturing defects or material inconsistencies will be addressed promptly. Our dedicated support team is readily available to assist customers through the warranty process, ensuring minimal disruption to your workflow.

FAQs of HR Slit Coils:

Q: How are HR slit coils typically used in industrial applications?

A: HR slit coils are primarily used in industries such as automotive, construction, and heavy machinery for producing components like beams, channels, and panels. Their high strength and malleability make them ideal for fabrication, welding, and forming processes.Q: What is the process of manufacturing HR slit coils?

A: The manufacturing process involves hot rolling steel slabs into coils, which are then slit to precise widths according to industrial specifications. This process ensures uniform thickness and quality, resulting in reliable coils tailored for industrial use.Q: When can I expect delivery after placing an order?

A: Delivery times may vary based on quantity and location, but we generally dispatch orders within a few days after confirmation. As a supplier and trader in India, we aim to offer prompt and timely deliveries to our customers across the country.Q: Where is your manufacturing and distribution facility located in India?

A: Our manufacturing and distribution operations are based in India. This strategic location allows us to serve clients efficiently across the nation, with support for logistics and timely supply.Q: What benefits do the 1-year warranty and grade D steel provide?

A: The 1-year warranty ensures your investment is protected against manufacturing defects, while the Grade D steel offers high durability and strength, resulting in a product fit for intensive industrial usage.Q: How does the silver color coating enhance the coils?

A: The silver finish provides not only an appealing appearance but also improves corrosion resistance, prolonging the lifespan of the steel in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+