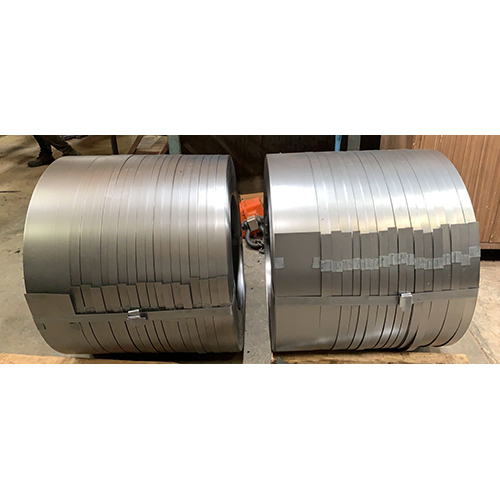

CR Slit Coils

Product Details:

- Usage Industrial

- Material Steel

- Technique Cold Rolled

- Grade D

- Product Type CR Slit Coils

- Color Silver

- Warranty 1 Year

- Click to View more

CR Slit Coils Price And Quantity

- 2 Ton

- 57 INR/Kilograms

CR Slit Coils Product Specifications

- Steel

- Cold Rolled

- Silver

- Industrial

- D

- 1 Year

- CR Slit Coils

CR Slit Coils Trade Information

- 100 Ton Per Month

- 2 Days

- All India

Product Description

A CR Slit Coil is a metal product that starts as a large Cold Rolled (CR) coil and is then precisely cut, or "slit," into narrower coils (often called strips or mults) of a specific, custom width.

Here is a detailed breakdown of its description, process, and applications.

1. Description and Characteristics

CR Slit Coils are defined by the material and the manufacturing step that creates them:

-

CR (Cold Rolled) Material: This means the steel has been rolled at or near room temperature, resulting in a product with:

-

Superior Surface Finish: It is smooth, clean, and often bright.

-

High Dimensional Accuracy: It has tight tolerances for thickness and width.

-

Enhanced Strength and Hardness: The cold-rolling process refines the materials structure, improving its mechanical properties.

-

-

Slit Coil (Strip): This indicates that a wider, original coil (often called a "master" or "mother" coil) has been processed on a slitting line.

-

Process: Circular rotary knives cut the wide coil lengthwise into multiple narrow strips.

-

Result: These strips are then re-wound into smaller, ready-to-use coils that meet exact width specifications.

-

Precision Cold Rolled Construction

Every CR Slit Coil is meticulously manufactured using a cold rolling process, which enhances strength and maintains a smooth surface finish. This technique yields tightly controlled dimensions and superior mechanical properties, making the product ideal for applications demanding accuracy and consistency.

Tailored for Industrial Demands

Designed for robust industrial environments, our CR Slit Coils offer flexibility across various manufacturing and engineering sectors. The grade D steel and 1-year warranty ensure these coils support heavy-duty usage and deliver outstanding results even in challenging operational conditions.

FAQs of CR Slit Coils:

Q: How are the CR Slit Coils manufactured?

A: The CR Slit Coils are produced using a cold rolling technique that compresses grade D steel at room temperature, creating coils with superior strength and a smooth silver finish. This process delivers precise thickness and excellent uniformity.Q: What are the primary uses of these CR Slit Coils in industrial applications?

A: These CR Slit Coils are widely employed in manufacturing, fabrication, and engineering industries where durable, high-strength steel is required. Theyre ideal for applications such as component manufacturing, structural supports, and machinery.Q: When does the product warranty apply and what does it cover?

A: The 1-year warranty is valid from the date of purchase and covers any manufacturing defects or faults under typical industrial conditions, ensuring customers receive reliable and high-quality coils.Q: Where are your CR Slit Coils available and can you supply across India?

A: As a leading manufacturer, supplier, and trader, we distribute our CR Slit Coils throughout India, ensuring timely delivery and consistent support to industrial clients nationwide.Q: What is the process for customizing the coil dimensions or ordering in bulk?

A: Clients can request custom coil sizes or place bulk orders by contacting our sales team directly. We accommodate specific project requirements and ensure each order is processed efficiently for prompt delivery.Q: How does the cold rolled technique improve product quality?

A: Cold rolling enhances the strength, surface finish, and dimensional accuracy of the steel, resulting in CR Slit Coils with excellent uniformity, durability, and performance advantages over hot-rolled alternatives.Q: What are the key benefits of choosing grade D steel CR Slit Coils?

A: Grade D steel offers a balanced combination of toughness and formability, providing superior resistance to wear and deformation. Coupled with cold rolling, it ensures the coils meet stringent industrial standards and deliver lasting performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+