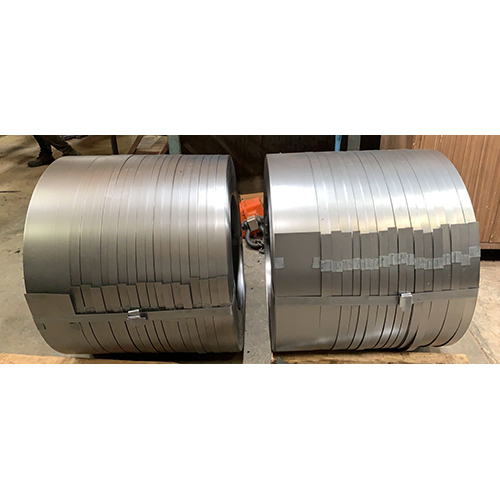

Stamping CR Coils

Product Details:

- Surface Treatment Polished

- Usage Industrial

- Material CR Steel

- Technique Cold Rolled

- Product Type Stamping CR Coils

- Grade D

- Coil Thickness 0.3 mm to 3.0 mm

- Click to View more

Stamping CR Coils Price And Quantity

- 2 Ton

- 57.0 INR/Ton

Stamping CR Coils Product Specifications

- 0.3 mm to 3.0 mm

- Industrial

- Standard

- 1 Year

- Silver

- Customized as per requirement

- Stamping CR Coils

- Industrial

- CR Steel

- Polished

- D

- As per requirement

- Cold Rolled

Stamping CR Coils Trade Information

- 100 Ton Per Month

- 2 Days

- All India

Product Description

The term "Stamping CR Coils" refers to Cold Rolled (CR) Steel Coils that are specifically selected and manufactured for use in metal stamping or deep drawing processes.

Stamping is a high-volume, precision manufacturing process where a flat sheet of metal (the coil) is placed in a stamping press, and a tool (the die) is used to transform it into a complex, three-dimensional shape through techniques like punching, coining, blanking, bending, and deep drawing.

Here is a description of the material and its key requirements for stamping:

1. Description of the Material

-

Base Material: Cold Rolled Steel Coil (often CRCA - Cold Rolled Closed Annealed).

-

Manufacturing: The hot-rolled coil is processed further at room temperature (cold reduction) to achieve tighter dimensional control and a better surface. Crucially, for stamping, the coil undergoes Annealing (heat treatment) to soften the steel and restore its ductility (the ability to be deformed without fracturing).

-

Form: Supplied as large, continuous coils which are unrolled and fed directly into high-speed stamping presses.

Precision and Quality for Industrial Stamping

Our CR Steel coils offer precise thickness control, uniform mechanical properties, and excellent surface smoothness, making them ideal for critical stamping operations. They are crafted to exacting industry specifications, ensuring reliable performance in demanding environments. Each coil can be tailored in length and weight, ensuring compatibility with your specific machinery and requirements.

Comprehensive Customization and Assurance

Choose from slit or mill edge finishes, a range of widths and thicknesses, and benefit from tailored coil weights. Each coil is processed with a polished surface treatment and is packaged to withstand export conditions. Our CR coils adhere to international standards and are backed by a 1-year warranty, providing assurance of quality and satisfaction for industrial clients.

FAQs of Stamping CR Coils:

Q: How are Stamping CR Coils manufactured and finished?

A: Stamping CR Coils are produced using the cold rolling technique, which enhances their surface smoothness and uniformity. The coils are polished to achieve a smooth, silver finish, and can be provided with either a slit edge or a mill edge according to the customers requirement.Q: What industrial applications are suitable for these CR coils?

A: These CR coils are primarily used for stamping in various industrial sectors, including automotive, appliance manufacturing, and other metal forming industries. Their dimensional precision and quality finish make them ideal for demanding forming or stamping processes.Q: When should I opt for slit edge or mill edge coils?

A: The choice between slit and mill edge depends on your processing requirements. Slit edges are suitable for applications needing tighter width tolerances and improved edge quality, while mill edges are typically used where standard edge conditions are acceptable.Q: Where are your Stamping CR Coils manufactured and supplied from?

A: Our Stamping CR Coils are manufactured, supplied, and traded from India, ensuring compliance with both local and international standards, with reliable distribution and export facilities.Q: What is the process for ordering customized coil size and weight?

A: You can specify the coil width, thickness (0.3 mm to 3.0 mm), length, and required weight when placing your order. Our team will tailor production and packaging to match your technical and logistical needs, adhering to your unique specifications.Q: How does the product benefit my stamping operations?

A: These CR coils offer a consistent, smooth surface and reliable mechanical properties, leading to reduced tool wear, improved formability, and fewer defects. The customization options and warranty ensure both performance and peace of mind for your industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+