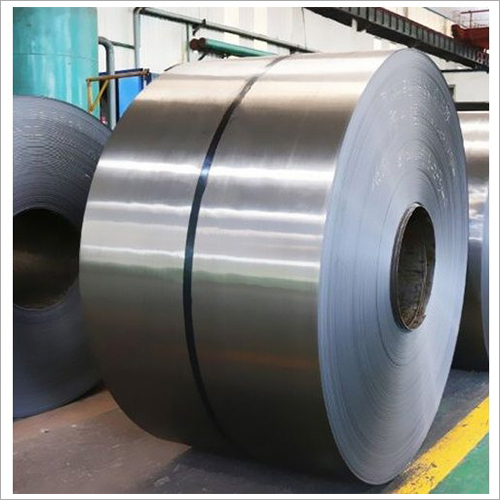

Mild Steel CR Coils

Product Details:

- Surface Treatment Polishing

- Usage Industrial

- Material Steel

- Technique Cold Rolled

- Product Type Stainless Steel CR Coils

- Grade D

- Color Silver

- Click to View more

Mild Steel CR Coils Price And Quantity

- 150 INR/Kilograms

- 2 Ton

Mild Steel CR Coils Product Specifications

- Cold Rolled

- D

- Industrial

- Stainless Steel CR Coils

- Polishing

- Steel

- Silver

- Industrial

- 1 Year

Mild Steel CR Coils Trade Information

- 100 Ton Per Month

- 2 Days

- All India

Product Description

Mild Steel Cold Rolled (CR) Coils are a flat steel product processed at or near room temperature. This process refines the materials properties, making it a highly desirable material for applications requiring superior finish, precision, and formability.

Here is a detailed description:

1. Manufacturing Process

Mild steel, initially produced as Hot Rolled (HR) coils, undergoes further processing:

-

Pickling: The hot rolled coil is cleaned, typically with acid, to remove surface scale (iron oxide).

-

Cold Rolling: The pickled coil is then passed through a series of rollers at room temperature (below the steels recrystallization temperature). This reduces its thickness, increases its strength and hardness, and improves dimensional accuracy.

-

Annealing (Optional but Common): The cold-rolled coil often undergoes heat treatment (annealing) to reduce internal stresses, improve ductility (ability to be formed), and soften the material.

-

Skin Pass (Optional): A final, light cold rolling to improve surface finish, remove minor defects, and control mechanical properties like yield point elongation.

-

Oiling: The finished coil is usually coated with a thin layer of oil to prevent rust and corrosion during storage and transport.

Superior Cold Rolling Technique

Mild Steel CR Coils are produced using the cold rolling process, which enhances their structural strength and surface finish. This advanced technique ensures dimensional accuracy, while maintaining the metallic luster and smoothness essential for industrial uses.

Reliable Industrial Performance

These coils are specifically designed for demanding industrial environments. Grade D mild steel is selected for high tensile ability and flexibility, making it ideal for fabrication, construction, and machinery manufacturing where both durability and adaptability are required.

FAQs of Mild Steel CR Coils:

Q: How are Mild Steel CR Coils manufactured?

A: Mild Steel CR Coils are produced using a cold rolling technique, where steel is passed through rollers at room temperature. This process refines the surface, ensures consistent thickness, and improves mechanical properties for industrial applications.Q: What is the primary usage of Mild Steel CR Coils in industries?

A: These coils are mainly used for fabrication, construction, automotive components, and machinery manufacturing due to their high strength, smooth finish, and versatility in forming or welding operations.Q: When should I consider using Grade D Mild Steel CR Coils?

A: Grade D Mild Steel CR Coils are recommended when your project requires dependable strength, formability, and resistance to deformation, especially in building structures, enclosures, and precision components.Q: Where can I buy Mild Steel CR Coils in India?

A: Mild Steel CR Coils are available from various manufacturers, suppliers, and traders throughout India. You can contact verified steel dealers or search online for distributors offering grade D coils with warranty assurance.Q: What benefits do Mild Steel CR Coils offer in terms of process and performance?

A: Their cold rolled nature provides tight dimensional tolerance, excellent surface quality, and increased tensile strength, resulting in improved efficiency during fabrication and prolonging product life in industrial settings.Q: Is there a warranty available for Mild Steel CR Coils, and what does it cover?

A: Yes, Mild Steel CR Coils come with a 1-year warranty, which typically covers manufacturing defects and ensures product quality, offering peace of mind for industrial buyers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+